On modern heat-transfer lines, many factories still rely on manual switching, loading, peeling, and unloading. This approach ties throughput to the pace of human work and makes quality control difficult to keep steady. The new generation of six-station fully automatic heat press changes that. It integrates previously separate steps into one collaborative system: material flows as the carousel rotates, stations hand off in rhythm, and the machine no longer waits for people—the production tempo runs itself. This is more than an upgrade in automation; it is a reconstruction of how production is organized.

1. Continuous Production with a Coordinated System

On conventional lines, the bottleneck often appears at the handoff between steps. Loading, transfer, peeling, and take-away look simple, but any delay or misstep breaks the beat. The six-station system removes that fragility by replacing human coordination with structured, station-level synchronization.

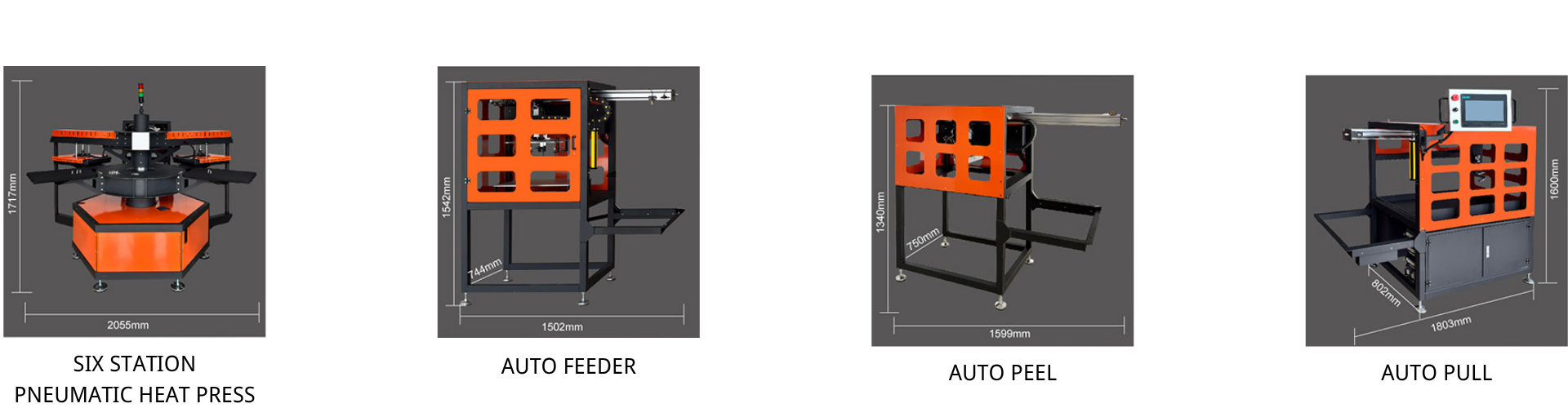

The carousel is the core of this logic. Six work tables rotate on a programmed cadence—one is loading, one is transferring, one is peeling, one is cooling. Because each station keeps working, idle time nearly disappears and the line becomes truly continuous.

Crucially, this continuity is not just “doing many things at once.” It is a form of beat optimization: dwell timing, rotation angle, and start order are calculated so that movements are smooth, thermal equilibrium is preserved, and energy use is minimized. For the factory, that translates into a steadier run curve and tighter product uniformity. Operators shift from repeating motions to managing tempo and monitoring data.

2.Fully Automated Workflow from Start to Finish

In traditional workflows, a lot of time is lost on small manual steps—lining up designs by hand, peeling film at just the right angle, and moving items carefully around hot surfaces. The six-station automatic heat press changes all of that. It turns those manual tasks into smooth, coordinated actions that happen the same way every cycle.

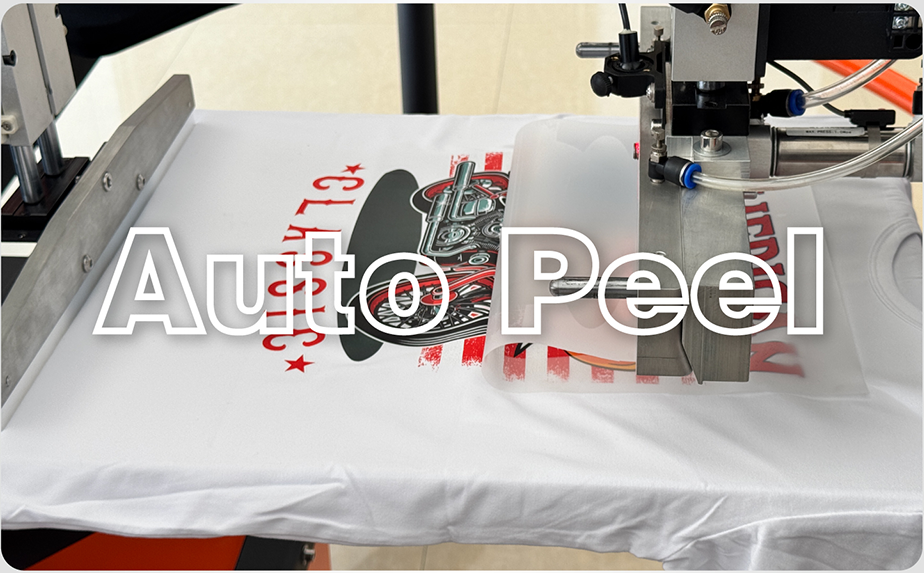

The Auto Feed system places the transfer in the correct position automatically. The transfer station applies the right time and pressure for each material. Auto Peel adjusts its speed and angle to match the film, keeping edges clean and details sharp. Auto Pull moves the finished items to the collection area safely, so operators never need to reach into hot zones.

All these steps work together like one continuous motion. The process no longer depends on human rhythm—it follows a steady, automatic flow. One operator can easily manage the whole system, and saved settings make it simple to repeat the same results every time.

3.Smart Structure for Stable Performance

In real industrial environments, speed is easy; stability is hard. Long shifts require a frame that holds position, a drive that stays accurate, and stations that can be serviced without halting the whole line. The six-station platform uses a modular architecture so each station can be maintained independently, while a center-drive carousel preserves positioning accuracy during rotation.

A reinforced spindle and arms resist thermal and mechanical drift, and the motion profile is tuned so that angle, order, and arrival time are monitored and corrected in real time. This dynamic balance keeps the cadence consistent hours into a run and keeps the output identical across shifts. For operators, the value is straightforward: easier handling, simpler upkeep, steadier results.

4.Intelligent Control for Consistent Results Conclusion

Traditional consistency depends on operator experience; different crews can produce small variations even with the same materials. With digital control, the machine stores process “recipes” for each substrate—cycle timing, rotation cadence, and module order—and recalls them without re-tuning. What used to be know-how becomes a parameter set.

Live monitoring records cycle durations, deviations, and system status. Alerts surface anomalies early, and production data becomes an auditable trail rather than a memory. Control shifts from people managing the machine to the system managing the process, so efficiency is traceable and quality is governed by logic rather than habit.

Conclusion

In the heat-transfer industry, technology does not evolve for show; it evolves to solve real production problems. A six-station fully automatic heat press represents more than a new machine—it represents a new way to organize work, where automation is not just about going faster but about making the production flow steadier, more efficient, and more controllable.

Post time: Nov-03-2025

86-15060880319

86-15060880319  sales@xheatpress.com

sales@xheatpress.com