Single Station vs. Dual Station Heat Press: Is the Upgrade Worth the Cost for DTF Shops?

Introduction: The "Idle Time" Problem in DTF Production

In the competitive Direct-to-Film (DTF) and Print-on-Demand (POD) sectors, the profit margin is defined by one metric: output per labor hour. Many shops begin with a standard single-station manual heat press due to the low barrier to entry. However, as daily order volumes exceed 100-200 units, the limitations of single-station workflow become glaringly obvious. Operators spend nearly 50% of their shift simply waiting for the 15-second press cycle to finish. This "idle time" is a silent revenue killer. This guide analyzes the operational ROI of upgrading to a Dual Station Heat Press, specifically comparing pneumatic and electric automation solutions to help factory owners make data-driven procurement decisions.

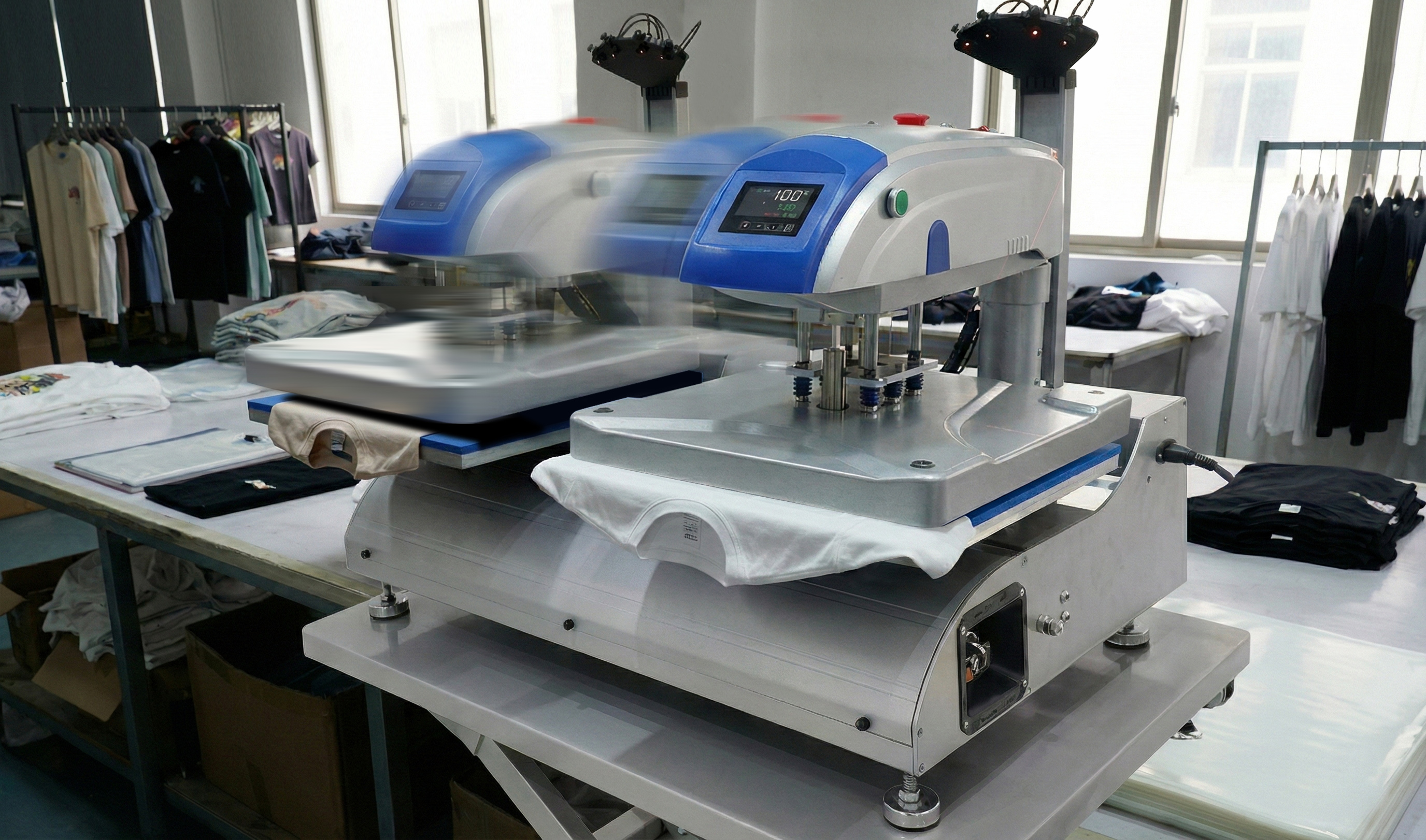

What is a Dual Station Heat Press?

A Dual Station Heat Press (often called a Twin Station or Shuttle Press) features two lower platens and one moveable upper heating head. The concept is based on a continuous "ping-pong" workflow: while the heating head is pressing a garment on Station A, the operator is simultaneously unloading the finished product and loading a new blank on Station B.

Continuous Workflow: Load on one side while pressing on the other.

Advanced industrial models, such as the EasyTrans™ Ultimate Level B2-2N (Electric) or B1-2N (Pneumatic), automate the movement of the head or the shuttle system. This eliminates the "stop-and-wait" cycle inherent in single-station machinery, effectively turning a batch process into a continuous flow assembly line.

Operational Pain Points with Single Station Presses

Sticking to single-station equipment in a high-volume environment creates three specific bottlenecks:

- Wasted Labor Hours: If a press cycle takes 15 seconds and handling takes 15 seconds, a single-station operator is idle for 50% of the production time.

- Inconsistent Peel Quality: Manual presses rely on operator physical strength for pressure. By the end of an 8-hour shift, fatigue sets in, leading to uneven pressure and peeling issues, especially with sensitive DTF films.

- Thermal Hazard Exposure: In single-station setups, the operator’s hands are constantly working directly under the heated platen during loading, increasing the risk of burns and slowing down movement due to caution.

Solution: The Shift to "Ping-Pong" Automation

Problem: A mid-sized apparel fulfillment center in Ohio was using four manual 40x50cm presses. They were capped at 800 shirts per day with four operators, and the noise from auxiliary air compressors for their older pneumatic units was violating local noise regulations.

Solution: The facility replaced the four manual units with two EasyTrans™ B2-2N Electric Dual Station Heat Presses. These units utilize an internal electronic motor to generate 360kg of downforce without an air compressor and feature a shuttle design for continuous loading.

Result:

- Efficiency: Daily output increased to 1,400 shirts using only two operators (one per machine).

- Cost Savings: The electric motor design eliminated the need for a 5-gallon air compressor, reducing electricity costs and maintenance headaches.

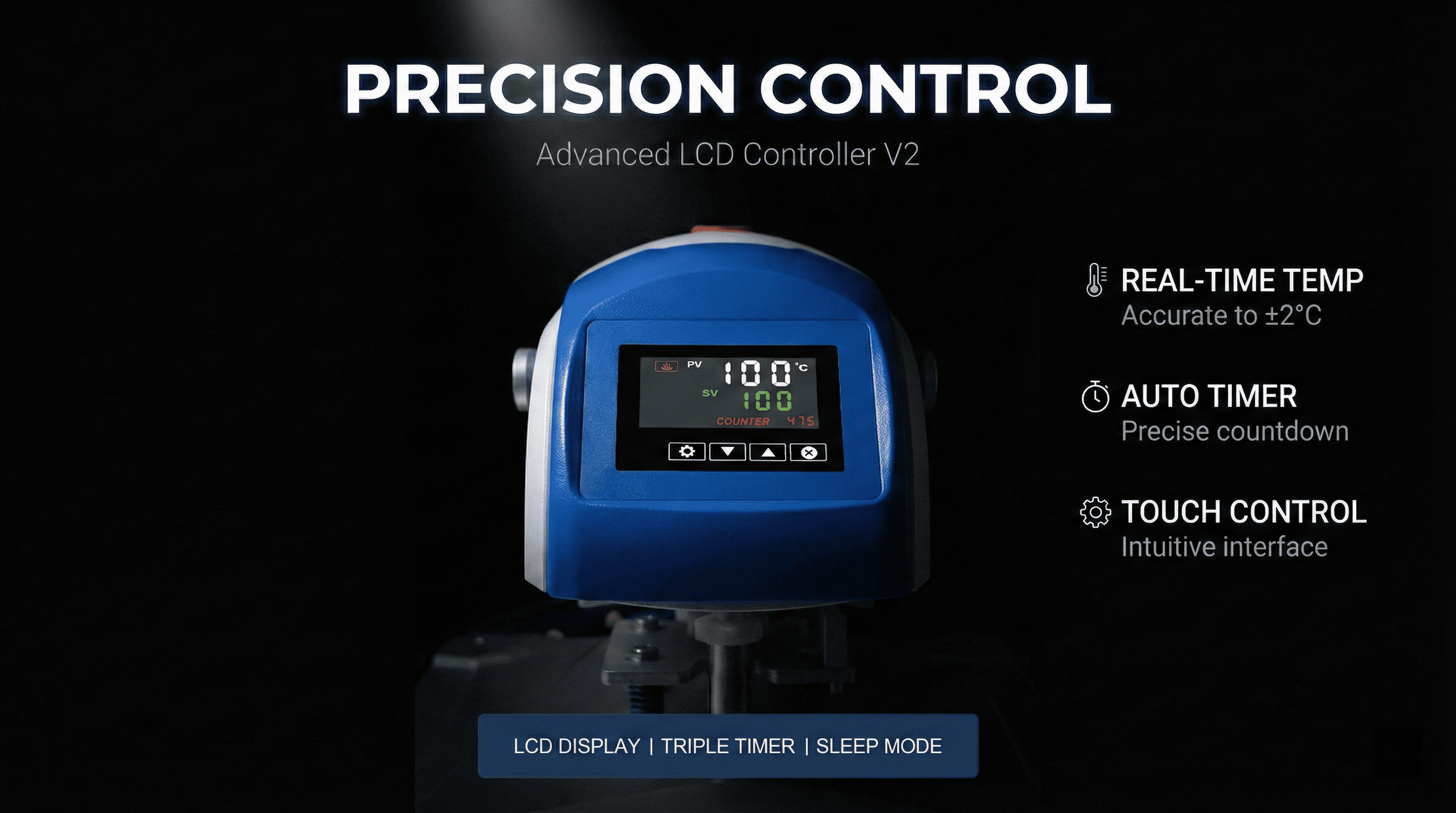

- Quality: The LCD Controller V2 ensured temperature accuracy within ±2°C, reducing the scrap rate to near zero.

Technical Comparison: Single vs. Dual Station Systems

To understand the upgrade value, we must look at the engineering data. The following table compares a standard manual press against the EasyTrans™ B1-2N (Pneumatic) and B2-2N (Electric).

| Feature | Standard Manual Press | EasyTrans™ B1-2N (Pneumatic) | EasyTrans™ B2-2N (Electric) |

|---|---|---|---|

| Workstations | 1 (Single) | 2 (Twin Station) | 2 (Twin Station) |

| Workflow Style | Stop-Wait-Load | Continuous Shuttle | Continuous Shuttle |

| Pressure Source | Manual Arm Force | Air Piston (Compressor req.) | Electronic Motor (No Air) |

| Max Pressure | Variable (Fatigue risk) | 450kg (High Pressure) | 360kg (Consistent) |

| Operator Efficiency | Low (50% Idle) | High (Zero Idle) | High (Zero Idle) |

| Noise Level | Silent | Loud (Compressor) | Quiet (<60dB) |

| Install Requirement | Standard Plug | Air Lines + Compressor | Standard Plug |

Key Buying Advice for B2B Procurement

When evaluating a dual station press for your production line, prioritize these three engineering specifications:

- Drive System (Air vs. Electric):

- Choose Pneumatic (like B1-2N) if you already have a central industrial air system and need extreme pressure (up to 450kg) for thick items like floor mats.

- Choose Electric (like B2-2N) for retail shops, mall kiosks, or offices. It offers "plug-and-play" simplicity, removes the risk of oil leaks from compressors, and provides sufficient 360kg pressure for all standard apparel and DTF transfers.

- Controller Precision: Look for advanced controllers like the LCD Controller V2 or IT9000 Series. These allow for digital pressure settings (on electric models) and auto-sleep modes (Max. 120 mins standby) to save energy and enhance safety during breaks.

- Safety Infrastructure: Industrial dual-station machines operate at high speeds. Ensure the equipment includes Triple Thermal Protection (separate live/neutral wire protection + overheat protector) and emergency stop buttons to comply with factory safety standards (CE/UKCA certified).

FAQ: Common Questions from Factory Owners

1. How much space does a dual station press require?

A dual station machine like the EasyTrans™ B2-2N measures approximately 94.7 x 72.5 x 71.5cm. While larger than a single station, it effectively replaces the output capacity of two single machines, actually saving floor space relative to productivity.

2. Is the electric motor durable enough for 24/7 production?

Yes. Industrial electric actuators are designed for high-cycle repetition. Unlike manual linkages that wear out physically, the electric motor provides consistent force with minimal maintenance.

3. Can I use different platen sizes on a dual station machine?

Absolutely. The EasyTrans™ series features a Thread-able & Interchangeable Base. You can swap the standard 40x50cm platens for smaller ones (e.g., for kids' wear or sleeves) in seconds without special tools, maximizing the machine's versatility.

Maximize Your Production ROI Today

Upgrading to a dual station system is not just an equipment purchase; it is a labor strategy optimization. If your goal is to double your daily throughput without doubling your payroll, the EasyTrans™ Dual Station Series offers the engineering solution your factory needs.

Contact our technical team for a Production Audit to calculate exactly how much labor cost you can save by switching to automation.

Post time: Feb-11-2026

86-15060880319

86-15060880319  sales@xheatpress.com

sales@xheatpress.com