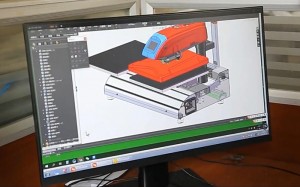

Heat Press Design

Engineers will design the heat press designing project according to market demand, i.e. OEM and ODM service.

Frame Laser Cut A

For thick metal frameworks, we will use Laser Cutter A which supports Max. 16mm thick metal cut at better performance.

Frame Laser Cut B

For thin metal frameworks, we will use Laser Cutter B which is faster and more economy to better control the manufacturing cost.

A heat press is a type of machine that utilizes heat and pressure in order to apply designs onto various substrates.

It uses a combination of pressure from the heated upper platen onto the lower platen in order to achieve its results.The majority of presses are used to apply heat transfers onto a range of garments. However, there is a range of different types of presses that can be used to apply such transfers to other items, such as mugs, caps, and balls, etc.

As a master manufacturer of heat press over 20 years experience, we would like to introduce how is a heat press be produced.

Frame Bending

After frame are laser cut, workers need to use hydraulic bending machine to shape the flat metal into desired structure like handle and control box, etc.

CNC Lathe Processing

For swing-away heat press, workers need to use CNC lathe to make the swing column and the joint tubes.

Mold Punching Shaped

Xheatpress has invested quite a lot of molds, workers will use the hydraulic punching machine and molds to shape the structures, spare parts like heating platen cover.

CNC Center Processing

As for some models have aluminum spare parts like rosin heat press, workers will use the CNC Processing Center to process the spare parts in high precision.

Holes Drilling

Workers will use punching machine or drilling machine to drill the spare parts holes, those holes are usually the connect joints or screws, nuts connect to.

Framework Welding

After all frame are cut, shaped. Workers put the frame pieces into framework by welding, we have 4 kinds of welding depending on spare parts dimension and thickness.

Framework Polishing

After frameworks are put together and welded, Xheatpress workers will polish the welding slag to make the welding joints smooth before powder spraying.

Rust Cleaning & Phosphatizing

Xheatpress is the ONLY ONE factory in China has pretreatment process before powder spraying, this will avoid the heat press being rusted in the future.

Powder Spraying

Xheatpress also powder spray the heat press in factory, moreover we support over 100 colors and painting finish in glossy, matte and orange skin.

Heat Platen Teflon Coating

Xheatpress also have heating platens coating line in factory, we have these heating platens double coated for anti-friction, anti-scratch and non-sticky purpose.

Terminals & Wiring

Xheatpress factory use UL/CE certified electric spare parts like SSR Relay, control panels, power cables, connecting wires. The qualified spare parts help to ensure our heat press in high quality and reliable.

Heat Press Assembly

Affter all sapre parts are prepared, well-trained Xheatpress workers will start to assembly the heat press, also have a pre-quality control, this will be 2nd QC. (1st QC is receiving check)

Heat Press QC

After heat press is assembled and pre-quality control check. Xheatpress QC team will have 3rd QC for overall check include function, performance, appearance, etc.

Cleaning & Packing

After QC team have the quality control, warehouse staffs will clean the heat press and have final quality control check, label the CE, packing the heat press with the power cable, user manual, etc.

Order Shipping

After heat press is packed, Xheatpress will store the heat press at warehouse. And prepare the shipping according to the order. We sincerely hope each customers will enjoy the heat press we supplied.

Post time: Sep-22-2022

86-15060880319

86-15060880319  sales@xheatpress.com

sales@xheatpress.com