Equipped with precision-focused and modernized technologies, these heat press offer unmatched services and come with low maintenance costs. Xinhong EasyTrans™ heat press machines are widely used in the printing industry due to their varied uses and high-quality printing works that they can perform. Regardless of what surface you are printing on, these heat press can perform equally well over all types of surface areas. These heat press can be used in several places such as manufacturing plants, residences, construction works, retail shops, printing houses and many more due to the A grade-quality print ink they work with.

Dual platen automatic heat press (Model # B2-2N Smart) is V3.0 version and updated based on B2-2N Basic and more user friendly and smart.

This electronic heat press is the top-of-the-line machine when it comes to mass production at high quality levels. This unit can handle anything – large or small garments, multiple ceramic tiles, and many other substrates. It does not require compressed air, which makes it more convenient. It features high efficiency & excellent pressure, can operate in full-auto, or semi-auto modes. With the multi-timers and foot pedal, users can make perfect job. This Easy-trans Smart level heat press has twin lower plates and could be semi-auto or fully automatic in a single switch. This electric heat pres is featured with a HMI/ PLC gauge, so user could control its shuttle moving speed, also able to have a trouble shooting when it’ s necessary. If user need to work with different size substrates, quick optional platen would be a good proposals, we’ve different platens and video uploaded on YouTube, here is the link, https://www.youtube.com/watch?v=T9yZXo6qkBk

As for Ultra Automatic Heat Press Machine (Model # B2-2N Smart), detailed introduction as bellow, if there is anything unclear, please email contact by sales@xheatpress.com or Whatsapp/Wechat contact by 86-150 6088 0319.

1.Control Panel Introduction

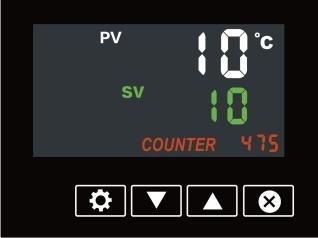

Control Panel Window

P-1: Temperature Setting

Touch SET button, continue with ▲/▼ button to set a desired temperature.

P-21: Timer 1 Setting (Pre-press)

Touch SET button, continue with ▲/▼ button to set a desired timer 1

P-22: Timer 2 Setting (Heat Press)

Touch SET button, continue with ▲/▼ button to set a desired timer 2

● Tip: Set P-22 data in 0 if Timer 2 is no required

P-23: Timer 3 Setting (Reinforced Press)

Touch SET button, continue with ▲/▼ button to set a desired timer 3

● Tip: Set P-23 data in 0 if Timer 3 is no required

P-3: °C/°F Temperature Read-out

Touch SET button, continue with ▲/▼ button to set a read-out

P-4: Pressure Setting

Touch SET button, continue with ▲/▼ button to set a desired pressure

● Tip: Pressure increases as P-4 data increases.

P-5: Standby Mode Timer Setting

Touch SET button, continue with ▲/▼ button to set a standby timer.

● Tip: Machine enters into standby mode when it’s not in use for P-5 period and reads OFF.

Heat platen stops heating and cools down. Control button touch waken up machine and heat platen heats up.

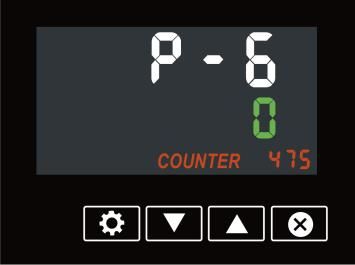

P-6: Multi-timer Switch

Touch SET button, continue with ▲/▼ button to set multi-timer, touch SET button to complete all settings.

Tip: P-6 read-out in 0, refers to single timer applied.

Tip: P-6 read-out in 1, refers to triple timers, usually applied to single platen. (i.e. timer 1 - timer 2 - timer 3)

Tip: P-6 read-out in 2, refers to triple timers and repeated, usually applied to dual platens. (i.e. timer 1 - timer 1 - timer 2 - timer 2 - timer 3 - timer 3)

2.Initial Position

Left Side as an initial position, user dual fingers click the start buttons (green buttons) get 2 results.

1.Heat platen returns to left side after click, next click makes heat platen close down.

2.Heat platen closes down if it’s already at initial left side.

3.Operation Introduction

Semi-auto Mode (Switch to Manual), green buttons control heat platen close and raise, pedal control heat platen shuttle between left & right station.

Automatic Mode (Switch to Auto), green buttons click to start the automatic mode according to the control system. (Tip: Pedal is disabled in Auto Mode.)

4.Dual Finger Click Mode

Heat platen closes when dual fingers click the green buttons, fingers are allowable to be released unless heat platen is closed firmly, otherwise heat platen will raise up.

5.Quick Release Button

Pause the release button, shuttle stops and heat platen raises up. After release button is reset and green buttons are clicked, heat platen will return back to initial left station as it may need.

6.Shuttle Speed

Heat platen shuttle speed control by the speed valve on machine body - Bottom Right

7.Pedal Control

Pedal control by one foot touch rather than long hold touch.

8.Connectors

Pedal connector and laser alignment switch are located on machine body - Right Front

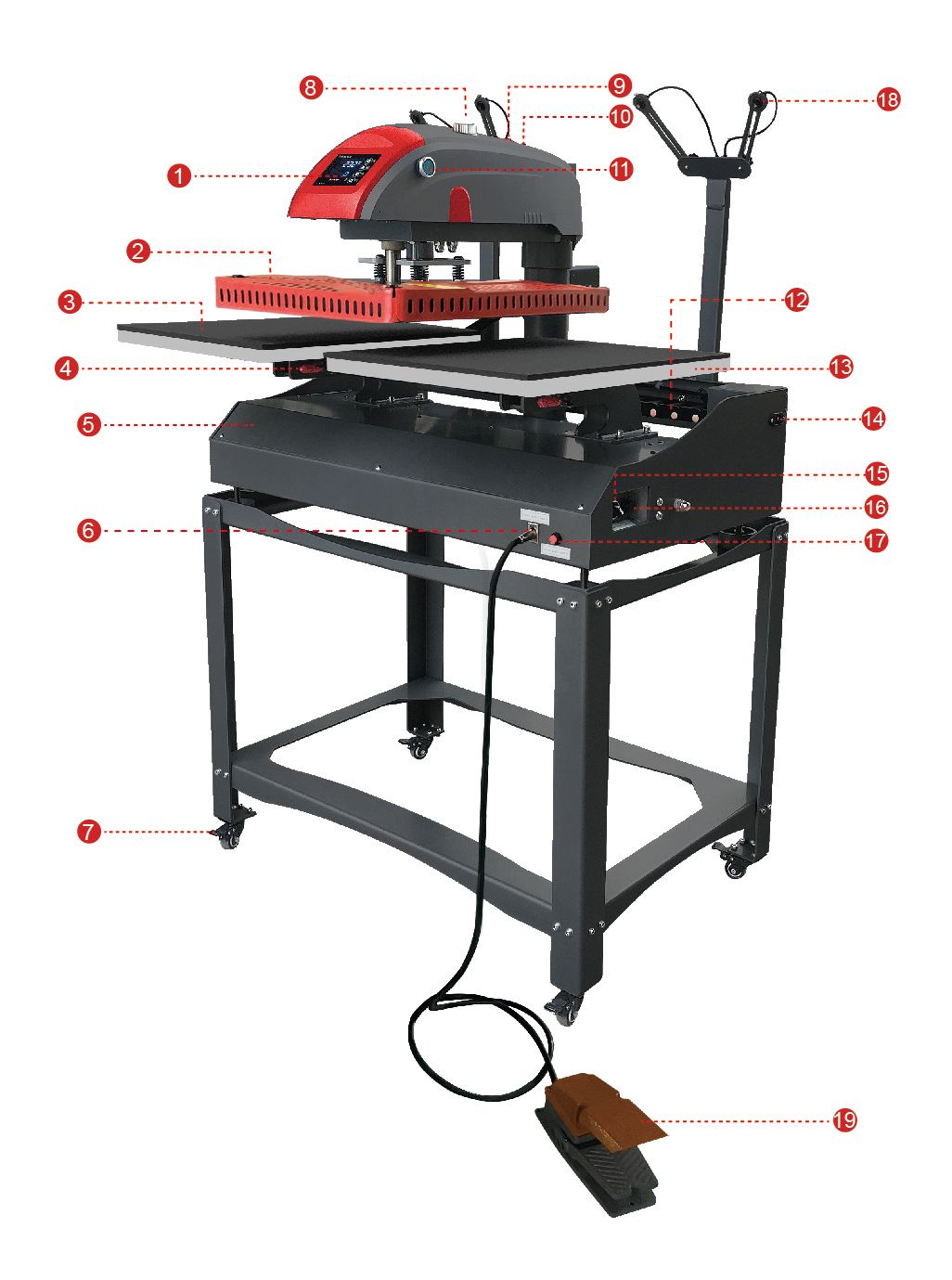

9.Machine Parts Introduction

1. Control Display

2. Heating Platen

3. Silicon Mat × 2

4. Quick Changeable Device

5. Machine Frame

6. Pedal Switch

7. Brake Caster

8. Quick Release Button

9. Power Switch

10. Thermal Breaker × 2

11. Operation Button × 2

12. Tank Chain

13. Lower Plate × 2

14. Power Plug

15. Manual/Auto-Switch

16. Shuttle Speed Controller

17. Laser Power Supply

18. Laser location

19. Pedal

Post time: Mar-03-2022

86-15345081085

86-15345081085  admin@xheatpress.com

admin@xheatpress.com